Tough, welded steel construction combined with a power transmission system that optimizes bending forces at a very affordable price point make Hochstrate bending machines the price-performance leaders in the industry. For mild steel, stainless, copper, Lexan, molybdenum, magnesium, aluminum, and plastics.

Tough, welded steel construction combined with a power transmission system that optimizes bending forces at a very affordable price point make Hochstrate bending machines the price-performance leaders in the industry. For mild steel, stainless, copper, Lexan, molybdenum, magnesium, aluminum, and plastics.

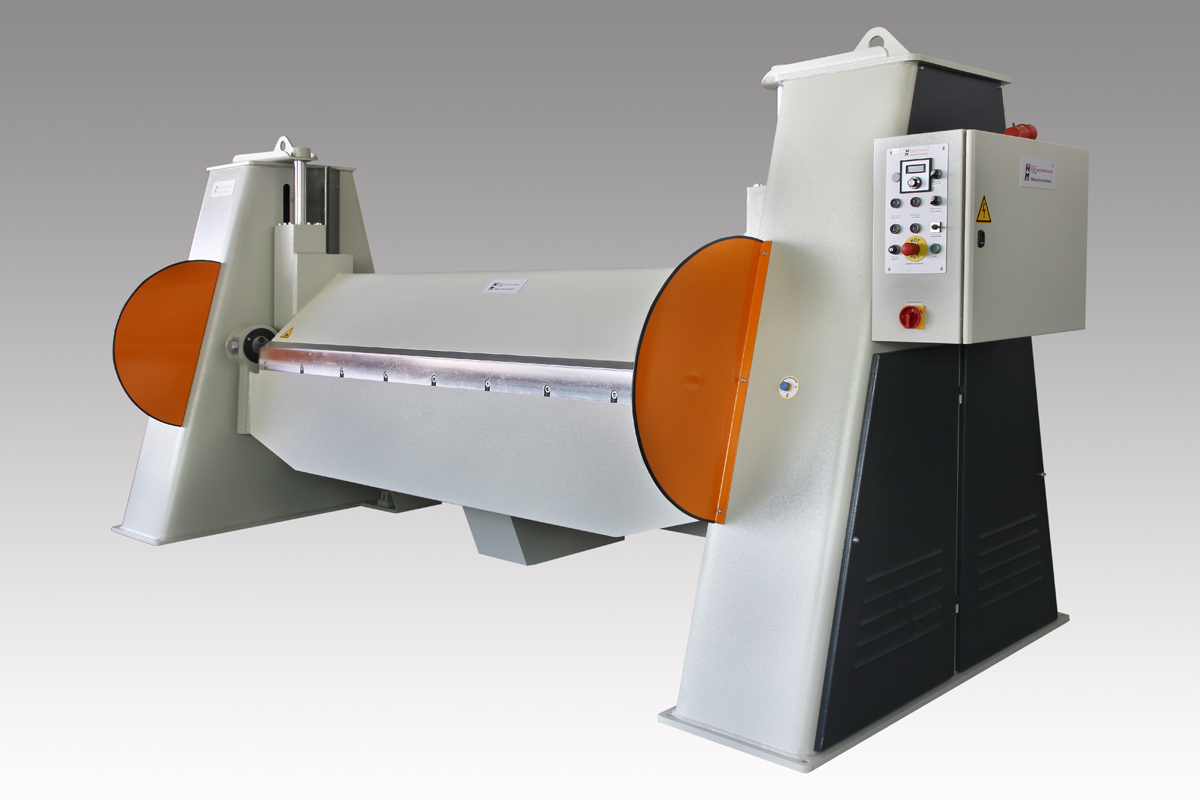

Hochstrate Folding Machines

Description

The perfect machine for every demand.

40 Years ago Dr. Hochstrate Maschinenbau developed its first hydraulic bending machine. Since then their portfolio has expanded to 160 basic machines with a wide variety of available customizations.

Tough, welded steel construction combined with a power transmission system that optimizes bending forces at a very affordable price point make Hochstrate bending machines the price-performance leaders in the industry.

Capacities: 500 to 8000 mm (19.7” – 315”)

Sheet thickness: 1 mm – 25 mm (19 GA – 1”)

Materials: mild steel, stainless, copper, Lexan, molybdenum, magnesium, aluminum, plastics

Custom Features

- Patented hydraulic dynamic camber-

- Electronic bending beam adjustment (available with automatic sheet thickness detection)

- Graphical touchscreen control stores up to 999 programs with 8 back gauge positions and 8 bending angles for each position

- Front gauging

- Back gauges:

- Manual

- Motorized, with electronic position indicator

- 1000 mm standard up to optional 8000 mm

- Radius bending function up to semi-circle (180°) or three quarter circle (270°) without tool changing

- Radius bending without tool change for cylindrical parts

- Radius bending of U-profiles

- Function extension “cone bending”

- Tools:

- Goat foot segments (sizes according to customer’s requirements)

- Heights: 50 to 300 mm

- Radius bending for varying diameters

- Segmented bending beam rail

- Custom rails

- Automatic clamping system available for:

- Upper beam tools

- Bending beam tools

- Stepless pressure regulation of upper beam

- Increased lift of upper beam to 1000 mm

- Swiveling upper beam

- Increased speed of bending beam

- Extension of bending beam to 150°

- Additional accessories are available on request

Standard Features

- Hydraulically operated upper beam and bending beam

- Upper beam 45° face angle

- Changeable tools for upper, bending and lower beam

- Electronic positioning of bending beam

- Control panel features:

- Digital display of bending angle

- Incremental control of bending angle

- Independent controls for operating upper and bending beam

- Switch for manual or automatic operation

- Siemens PLC-Control

- Foot-actuated switch for both manual and automatic operation

- CE-certification

- Upper beam safety stop at 25 mm clearance