Until Rodstein came on the scene there wasn’t much excitement in the busbar punching and bending industry. Rodstein’s automation revolution in copper and aluminum busbar production changes that.

Until Rodstein came on the scene there wasn’t much excitement in the busbar punching and bending industry. Rodstein’s automation revolution in copper and aluminum busbar production changes that.

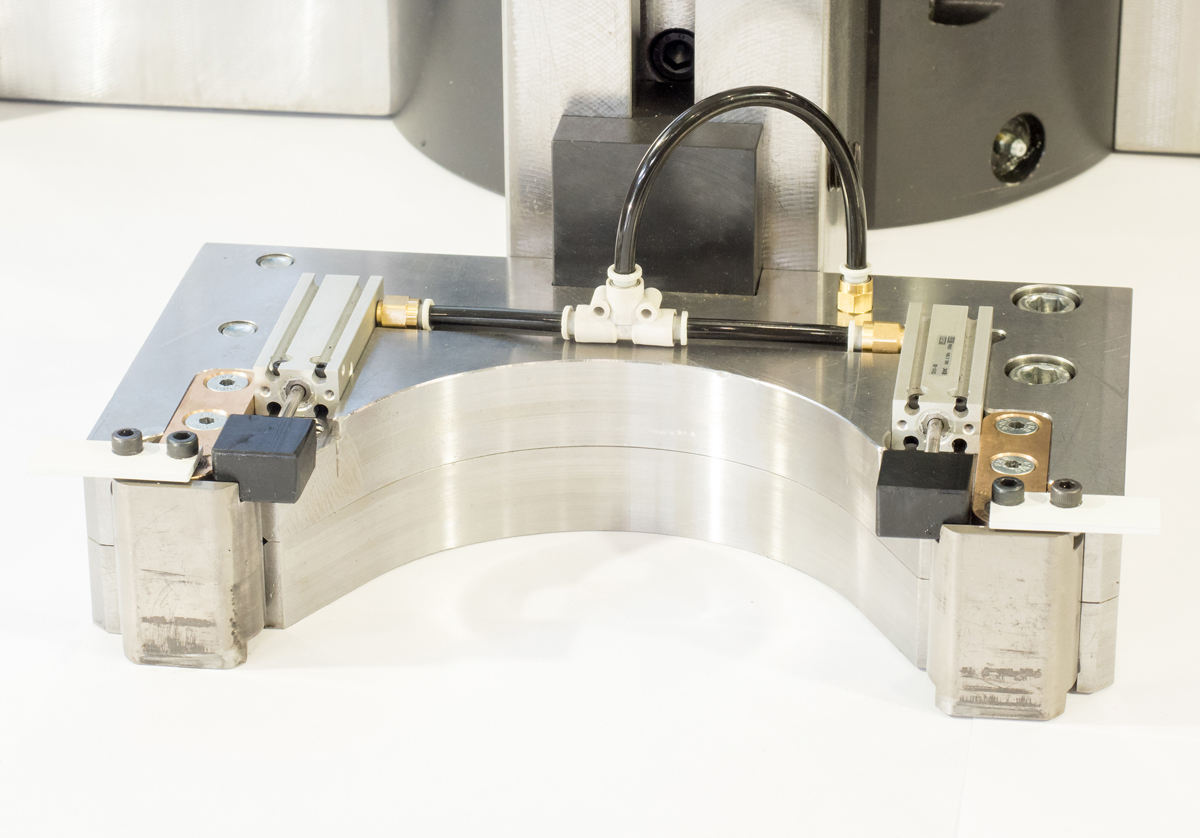

RodFORM Busbar Bending Machines

Description

If you are ready to revolutionize your busbar production while cutting costs, then consider what Rodstein’s robotic busbar processing has to offer:

- All electric, servo-driven machines. No hydraulics.

- Outstanding energy efficiency

- Unsurpassed production speed

- Automatic tool-changing

Main Features of the RodFORM Bending Machine

- Servo-electric flat bar bending, maximum ram force 200kN

- Flat bar maximum width up to 200 mm (7.8”) for thicknesses 3 mm-15 mm (.12” – .6”)

- Rodstein CNC-system built on Beckhoff open-control platform

- Beckhoff AC-servo-drives and motors

- Graphical user interface with Windows Æ-based touch screen

- USB port and Ethernet connection for program transfer

- NC controlled positioning device, movement length 2175 mm (85.63”)

- Angle measurement and correction

- Teleservice

- CE safety approved

Custom Features

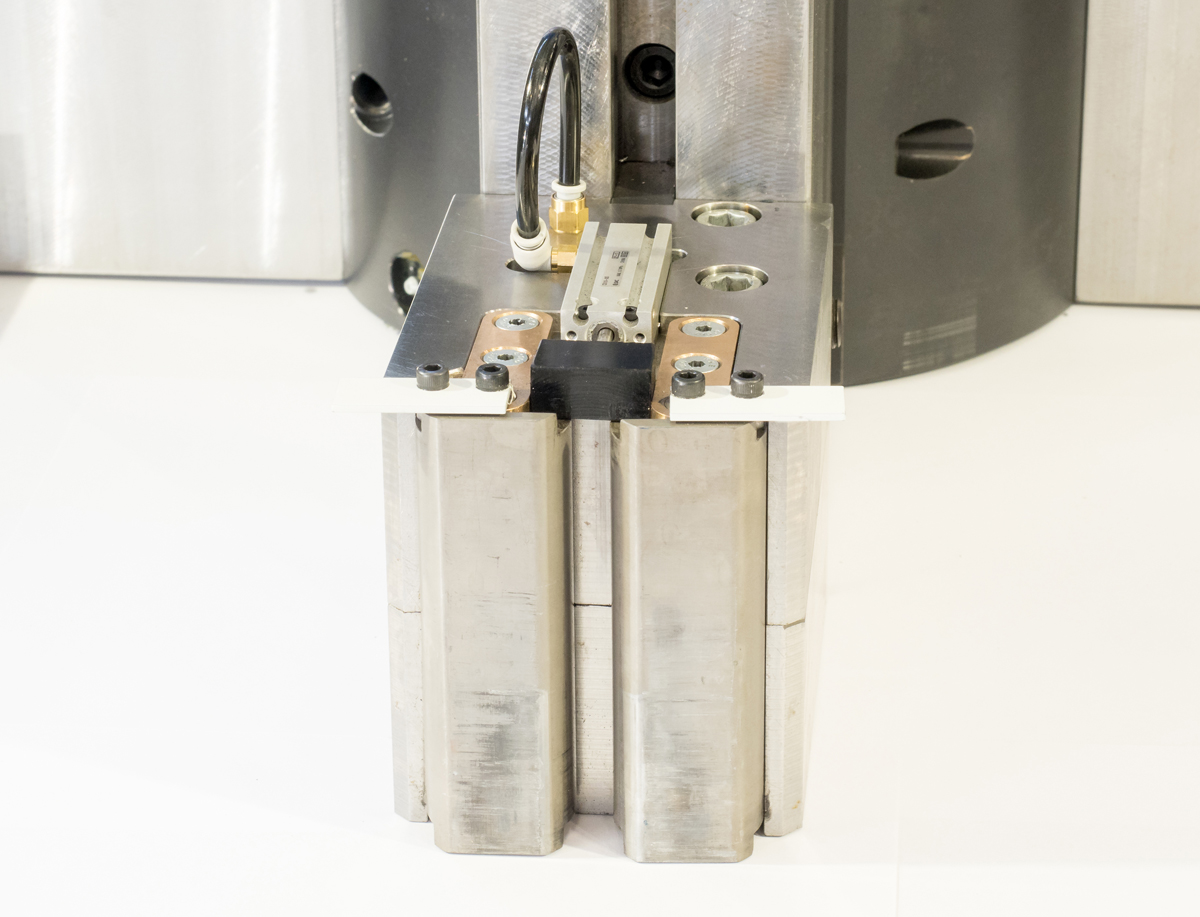

- RodLEAN automatic tool magazine

- Reduces setup time

- Four tool capacity

- Auto change time < 4 seconds

- Max. tool height 200 mm (7.87”)

- Tooling

- Tooling: Normal Bending

- Punch and die set

- H50 – 200 mm (7.87”)

- V 34-90

- V 130-230

- Tooling: Side Bending

- Punch and die set

- R 20-120

- V 100 – 600

Standard Equipment

- Beckhoff Embedded PC with Intel Atom 1.75GHz, 2Core processor

- RodFLAT software with RodFORM graphical user interface

- Powerful PLC and motion control system

- TwinCAT automation software

- 18.5” touch screen

- Servo-electric bending

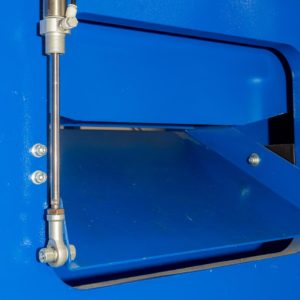

- Loading table

- Load on left or right side

- Back gauge movement length: 2175 mm (85.63”)

- Graphical part programming